AHBS Denitrifying active sand biofilterDenitrifying biological filter powered by air source

AHBS Denitrifying active sand biofilter

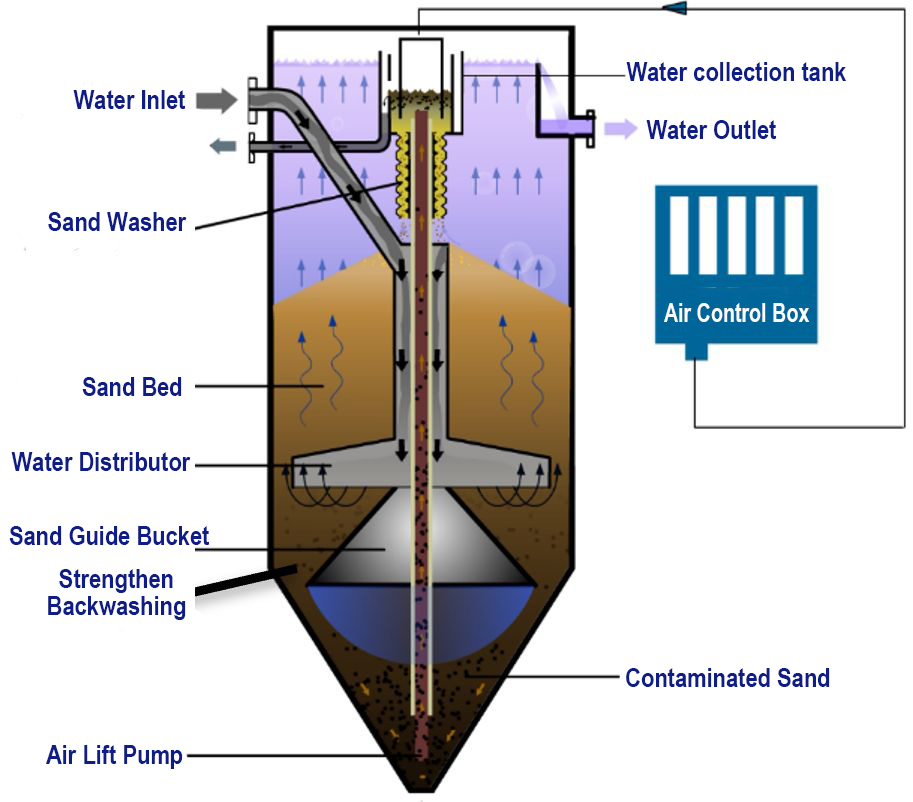

Denitrifying biological filter powered by air sourceProcess IntroductionProcess IntroductionAHBS Denitrifying Activate Sand Biofilter is a high-efficiency filter that integrates filtration and biological treatment, developed through technological improvement and innovation on the basis of traditional activated sand filters The main technical features of AHBS denitrification active sand biological filter are as follows: Unique mode of operation Filtration and cleaning are carried out at the same time, which overcomes the problem of easy blockage of static filter and large amount of washing water. Lower filter speed (filter speed control in 3.5 to 4 m/h), the conventional washing and strengthen photo development, process automatic control, powered by air source, without washing system of water pump, low energy consumption, harden, jams, the filter material layer water use ratio is low. Special composite filter material For different nature of sewage and effluent discharge standards, different high porosity composite filter media can be used, the filter media has large specific surface area, selective adsorption capacity, strong impact resistance to fouling, easy to hang film, biological co-regeneration, wide range of application, good filtration effect, and has good decolorization effect. The application scenarios of AHBS Denitrifying active sand biofilter are mainly as follows: ü Drinking water treatment ü Industrial wastewater treatment, ü Urban sewage treatment, ü Water resources cycle

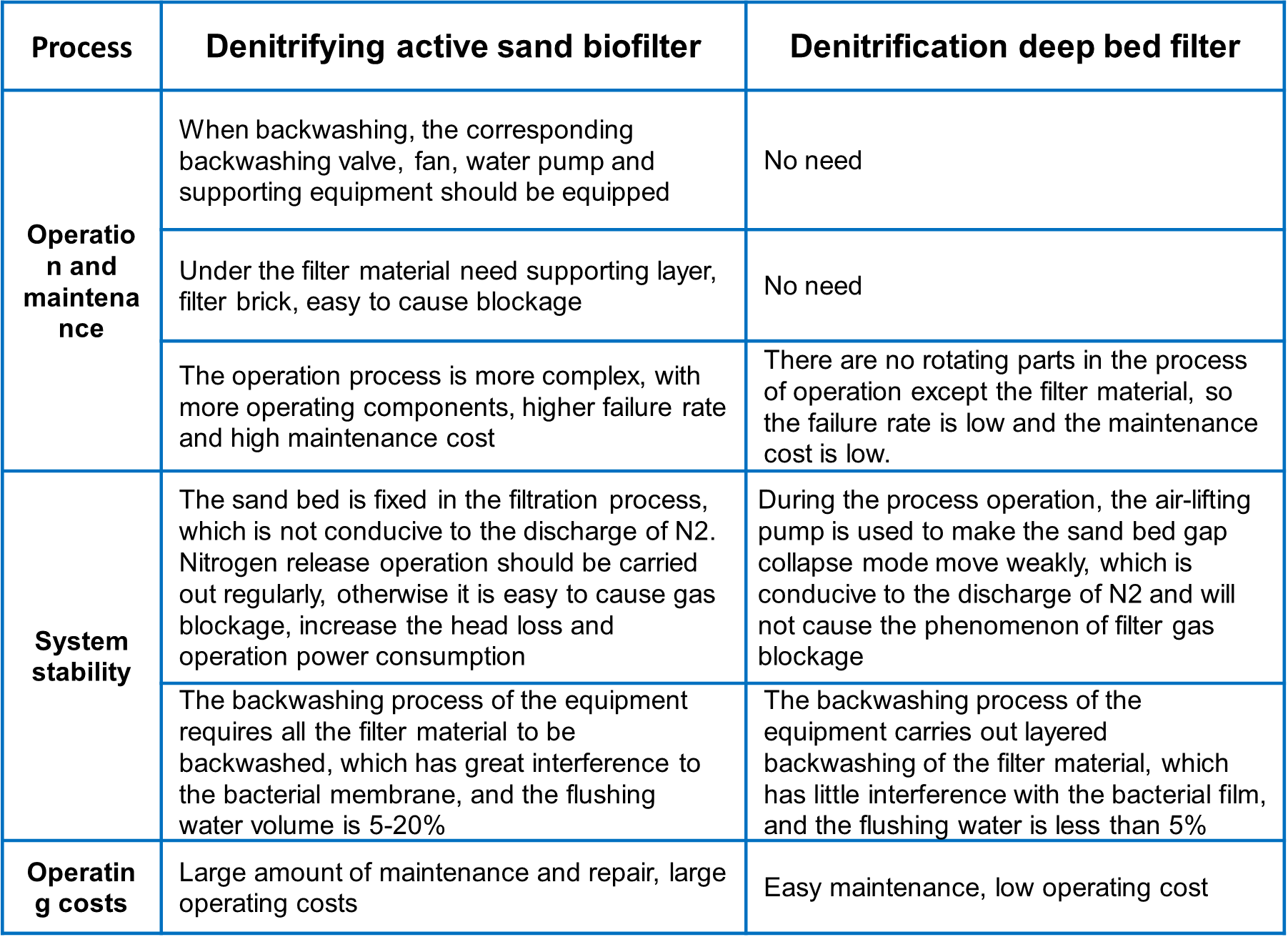

Performance comparison of denitrifying active sand biofilter and deep bed filter

Technological AdvantageTechnological Advantageü Save space and complete filtration and denitrification biological treatment functions within the same filter; Can effectively remove SS and TN from raw water; ü No need for high head and large flow backwash pumps, further reducing operating costs; ü Easy to maintain, without any rotating parts except for the specialized composite filter material, with low failure rate and low maintenance costs; ü Low head loss. Due to the singularity of the filtration process structure and the particularity of the composite filter material, the filtration head loss is small, generally ≤ 0.8m; ü Easy to operate, good filtration effect, strong impact load resistance, high-quality and stable effluent effect, without periodic water quality fluctuations; ü The composite filter material has a large specific surface area, strong adsorption and interception capabilities, and can selectively and efficiently remove organic matter, ü The system operates automatically, with automatic backwashing every 24 hours; Flushing water volume ≤ 5%, regular inspection and maintenance; ü Loss of ultra-low filter material. The anti sand device ensures that the loss rate of filter material is less than 1% of the total amount of filter material added for two years. |