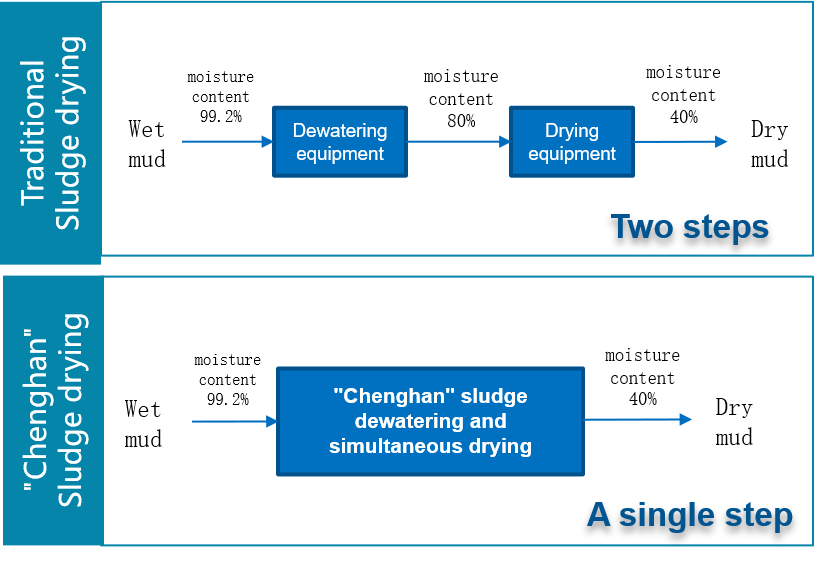

Process introductionProcess introductionThe "Chenghan" sludge dewatering and simultaneous drying technology adopts pressure resistant and superconducting nano materials, combined with low-temperature wall breaking technology and vacuum drying process, based on the plate and frame pressure filtration technology. After the sludge is treated through a process of simple feed conditioning, double diaphragm thermal pressure filtration, and vacuum dehumidification, the moisture in the sluge is fully removed, and the moisture content is dehydrated from ≥ 99% to ≤ 40% in one step, greatly reducing the sludge amount, Significant savings in sludge treatment, transportation, and disposal costs, saving energy and increasing efficiency by over 60% for enterprises, significantly achieving sludge reduction. Process CharacteristicsProcess CharacteristicsStabilization: the sludge moisture content is reduced from 99% to less than 40%. mud cake property is stable, avoid secondary pollution. Reduction: Without the addition of inorganic agents such as lime, the dosage of the agent is small, the cost of the agent is reduced, and the additional increment of the sludge is reduced, and the cost of the final disposal of the sludge is low. Harmless: Through a certain temperature to kill bacteria in the sludge, parasitic eggs, closed operating space, no dust, odor and other emissions, to ensure a good working environment. Recycling: The dried sludge is sent to cement plants, power plants and other collaborative incineration, all to achieve recycling.

|